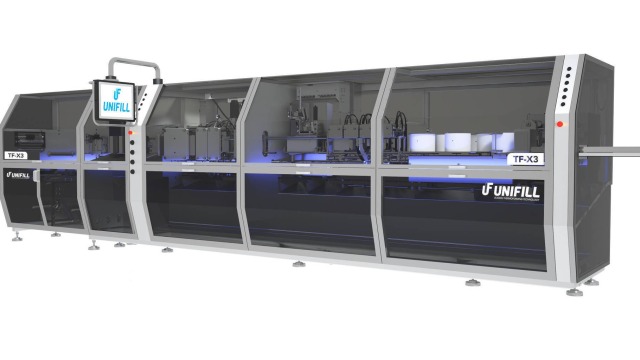

With the TF-X series, UNIFILL Srl presented its new generation of thermoforming machines at interpack 2023. Several new developments from UNIFILL combined with Bosch Rexroth drive technology without control cabinets result in a modular machine concept with new functionalities that can be flexibly adapted to customer-specific requirements.

With Generation X, UNIFILL has developed a new machine concept for its thermoforming technology. The machine with up to 35 cycles per minute is suitable for filling liquid and semi-solid products in single-dose packaging for the food and non-food industry. Scalable solutions from Rexroth reduce control cabinet size and wiring effort. The IndraDrive Mi drive technology without control cabinet meets the high performance required in the production of pouch packaging and supports the precision and flexibility of the new machine type.

New functionalities

With this generation of machines, UNIFILL also offers new technology options: Data processing, predictive and preventive maintenance and a new HMI interface simplify interaction between operators and the machine. Based on solutions from Rexroth's ctrlX AUTOMATION modular automation system, it also opens up a high degree of flexibility. The basis is the latest app technology: via the ctrlX Store, users can obtain apps from Rexroth or apps from third-party providers, or create apps themselves. For example, IoT functionalities or other options desired by end users can be installed. Machines can be scaled and customised on this basis. An OPC UA interface also enables a secure connection between the machine and the entire plant.

TF-X3 vertical thermoforming machine from UNIFILL for filling liquid and semi-solid products in single-dose packaging for the food and non-food industry (Image source: UNIFILL Srl)

Exploiting synergies

Thanks to UNIFILL's investment in research and development and Bosch Rexroth's support, the TF-X series is equipped with future-oriented functionalities. Synergies quickly emerged within the framework of the cooperation. This enabled the ambitious goals to be achieved quickly.

Increase sustainability

Sustainability and environmental compatibility are important corporate priorities at UNIFILL. More and more functions for saving energy are also being integrated into automation components. Bosch Rexroth offers solutions for energy monitoring as well as functions for increasing energy efficiency. For example, the ctrlX CORE controller from the ctrlX AUTOMATION modular automation system makes it possible to collect and evaluate information from all machine components. Intuitive dashboards immediately display processed data and statistics.

In addition to classic paper solutions, UNIFILL also wants to use recyclable materials with a polymer such as mono-PT, PET or PP in the future. This saves resources and protects the environment.

Learn more about the ctrlX AUTOMATION modular automation system.

Author: Tobias Gerhard

Position: Senior Business Development Manager Consumer Goods in Central Europe Sales, Bosch Rexroth AG