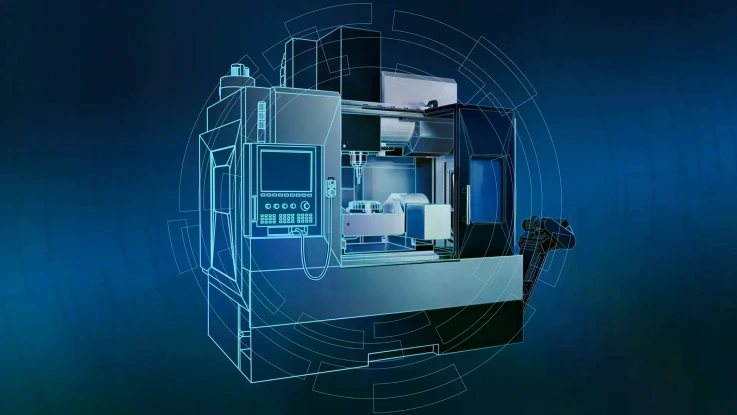

Linear motion technology from Rexroth can be used universally and optimizes the processes in both cutting machine tools (e.g. milling, turning and grinding centers, as well as processing centers) with the highest level of precision, as well as in forming machine tools (e.g. presses, punching and bending machines), thus enabling the absorption of high forces, fast travel speeds and short cycle times.

Machine tools with even greater precision? Increased automation capabilities? And improved sustainably? Optimize your production with our innovative linear motion technology solutions. We’ll show you how you can easily compensate for thermal effects using patented linear guides or drive your transformation towards new markets and applications with automation solutions. Discover your production potential. Let’s do it together.

FAQ

Excellence in linear motion technology for modern machine tool construction: As a leading partner in the machine tool industry, we know that every detail matters. Here you will find answers to the most frequently asked questions about our linear motion technology, which has been specially developed to take the precision, dynamics and efficiency of your machines to a new level.

In which machine tools is Rexroth linear motion technology used?

How do I achieve the highest level of precision and rigidity in a machine tool, and what contribution makes linear motion technology?

Rexroth profiled rail sytems and ball screw assemblies are specially designed for the high requirements in the machine tool. They offer maximum stiffness, a low-pulsation sequence and high load-bearing capacity to dampen vibrations and safely absorb process forces, even with aggressive cutting parameters. The result is superior process stability, which ensures highly precise processing even under the most demanding conditions. For profiled rail systems, it is important to select the correct accuracy classes and pre-tensioning for the rails and guide carriages. We recommend the high accuracy classes, e.g. SP or UP, and a medium to high pre-tensioning for the guide carriages. The "Selector" design tool from Rexroth is helpful in this regard; it suggests the appropriate solution based on the application parameters. In special applications, Rexroth also offers a calculation service with advice from experts to ensure an ideal design of the linear technology in the machine.

What measures are you taking to ensure thermal stability in the machine tool?

Thermal stability is the key to maximum precision. Our linear motion technology solutions include temperature management. With the patented Thermo Compensating Rail System TCRS, a cost-effective and flexible solution is available for the first time: heat can be removed directly from the linear guide or supplied at the start of production. The thermal stability minimizes scrap and increases productivity enormously, particularly as there is no need to readjust process parameters. For systems with ball screw assemblies, Rexroth relies on hollow-bored and liquid-cooled spindles. This active temperature control transfers the process heat generated by the high friction during fast traversing movements directly to the source. Alternatively, in the case of ball screw assemblies without temperature control, the linear expansion can be compensated by the integrated measuring system IMS from Rexroth. In closed-loop mode, the direct measuring system eliminates all faults in the mechanical drive train.

How is the durability and low maintenance of linear motion technology components ensured and what role does predictive maintenance play in this regard?

Our linear motion technology products are designed for maximum service life under production conditions. We only use components with the highest load ratings and optimal lubrication and sealing concepts. A central element in this process can be an automatic central lubrication system, which supplies all profiled rail systems and the nuts of the ball screw assemblies with lubricant as required. Robust covers and wipers protect the sensitive guideways against chips and cooling lubricants and prevent lubricants from escaping.

For predictive maintenance, there are sensors in the integrated measuring systems of the profiled rail systems for monitoring vibrations and temperature. With electromechanical cylinders, the condition of the lubrication can be monitored in addition to the temperature by using a sensor package. This makes it possible to plan machine maintenance and maximize machine availability.

What are the advantages of integrated measuring systems IMS in machine tools compared to glass scales?

Compared to traditional machine concepts with external glass scales, the integrated measuring systems from Rexroth do not require any additional attachments. This reduces the installation space, as the measuring function is included directly in the profiled rail systems. Complex alignment processes are not required and enable fast commissioning. The robust, encapsulated design directly in the guided rail system ensures a permanently higher system rigidity and precision. In combination with IMS and TCRS (Thermo Compensating Rail System), an ideal thermal coupling between profiled rail system, measuring system and machine bed is ensured - guiding, tempering and measuring in one system.

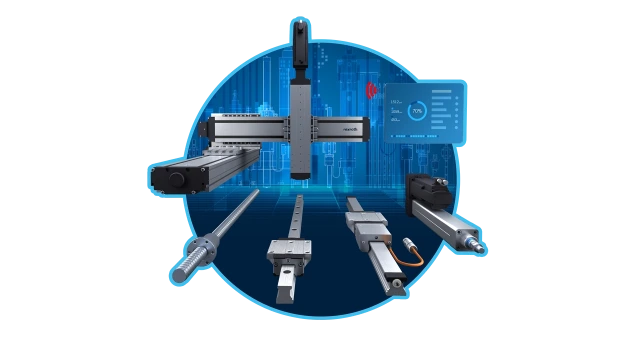

What solutions are available for automation in and on the machine tool using linear motion technology?

At Bosch Rexroth, machine manufacturers can find a wide range of linear axes and actuators, as well as complete multi-axis systems (linear robots) for the automated handling of tools or workpieces. Modular sub-systems are also increasingly being developed for the loading and unloading stations. Typical tasks, such as off-press or pressing, can be implemented in a space-saving and cost-effective manner.

What contribution does linear motion technology make to energy efficiency in the entire machine tool?

Rexroth relies on low-friction profiled rail systems and high-efficiency ball screw assemblies to minimize electrical drive power. Thanks to the different sealing variants, low-friction solutions can also be configured. In addition, the cornerstone for the resource-saving use of linear motion technology components and systems is already established during the design and dimensioning - avoiding over-engineering. Bosch Rexroth makes this possible through customer-specific advice and application support, as well as through the online design and calculation tools.

Contact us now

We know not only our technologies but also the machine tool market inside out. As a result, we can quickly find the right solution for your future production.