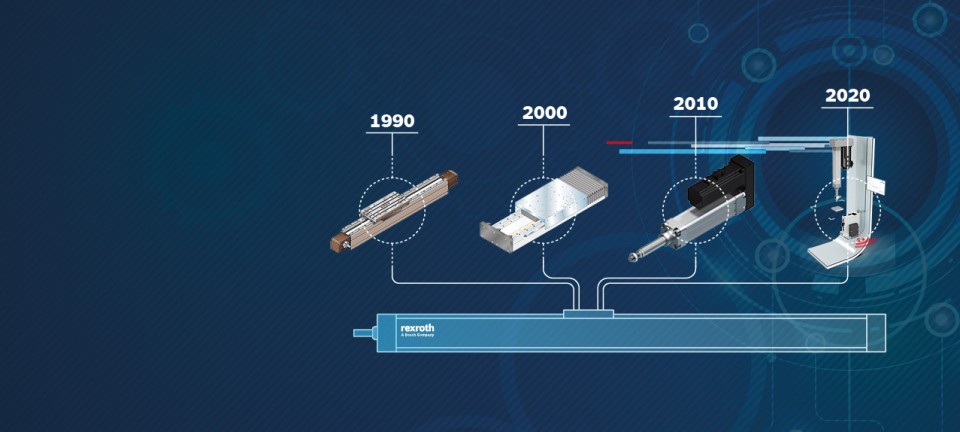

Quantum leap: Expanding the traditional linear axes range (linear motion slides, transfer tables) through the use of high-precision ball rail systems in the innovative linear axes ball rail tables and linear modules.

Benefits:

- Increased power and a reduced footprint

- Much greater precision

- Longer service life