How to reliably and efficiently tighten battery packs for electric vehicles.

Battery packs for electric and hybrid vehicles must be tightened under current. Because assembly errors pose a risk to workers’ health, the proper functioning of the vehicle and its safety system, there are strict requirements concerning mandatory monitoring and documentation. What solutions does Industry 4.0 provide for tightening connections in production and service that both conform to standards and are economical?

Slowly but surely e-mobility is gathering momentum. It is estimated that nearly 20 million hybrid and electric vehicles will be produced in the year 2025. Production and service managers are called upon to prepare production lines and workshops accordingly. In the coming years, there will be plenty of battery packs that, depending on the model, are assembled with several hundred bolts and greatly impact the power, range, service life, and vehicle safety in particular. If individual components fail while driving, there is a danger to life, limb, and the environment. Consequently, in accordance with VDI/VDE standard 2862, suppliers and OEMs must precisely monitor every single safety-critical tightening connection and archive the documented data for ten years. Many managers want to know how they can implement the transition in production and service cost-effectively and efficiently and at the same time ensure process quality.

Safety-critical tightening connections for complex battery assembly: In Bosch’s Bamberg factory, an intelligent cordless nutrunner with integrated sensors prevents expensive rework as well as injury and product liability risks.

A battery pack is a complex system comprising a controller, housing parts and numerous battery modules made of lithium-ion cells, which come from the factory partially charged. Even repairs – such as replacing a module – are typically performed while under current. A short circuit at 400 to 600 volts could be deadly. Using hand-held tightening tools connected by a power cord involves the risk of unintentionally transferring electrical potential over conductive metal parts, from the nut to the nutrunner and from there to the controller. Of course, this also poses a considerable risk to the worker who is holding and operating the hand-held nutrunner. To prevent injuries, environmental damage and product liability cases without jeopardizing profitability, reliable, intelligent and scalable tightening solutions are required which are capable of recording and transmitting data wirelessly.

One such all-in-one solution, which suppliers and OEMs can use to easily meet the requirements of VDI/VDE 2862 while providing workers with maximum safety, was tested for several years in Bosch Rexroth’s battery production and eventually launched on the market. It combines a fully insulated, Nexo cordless nutrunner with the protective insulation, NXAP030/ NXPP012 designed specifically for battery assembly, and thus not only provides protection against accidentally placing the nutrunner on parts of the battery that carry voltage but also against transferring voltage to the nutrunner. The design of the protective insulation in the current class up to 800 V is confirmed by Dekra. The protective insulation also prevents loose clothing from getting caught in the output drive.

Protective insulation for the output drive and tool mount protects workers against dangerous voltages: 400 volts and higher can be present when assembling batteries for electric vehicles, but precautions should already be taken at 48 volts.

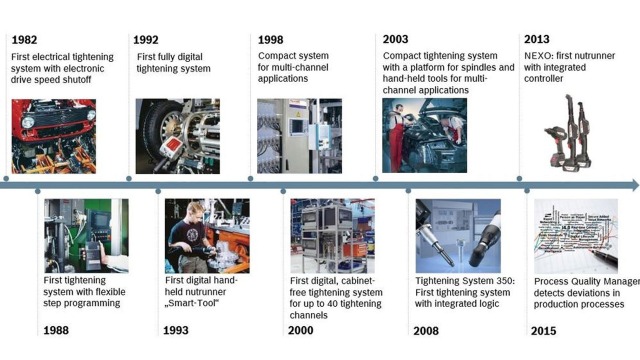

Rexroth has packed over 30 years of technical expertise in controlled Tightening Technology into its intelligent Nexo cordless nutrunner. In 1982, the company introduced the world’s first electrical tightening system with electronic drive speed shutoff. In the next ten years, the first tightening system with flexible step programming and the first fully digital tightening system followed. Exactly 20 years before the Nexo, the world’s first digital hand-held nutrunner made its debut. The multi-channel capability and integrated logic of this innovative technology continues to this day. The latest milestone is the Process Quality Manager, a software solution developed in collaboration between Bosch Rexroth and Bosch Software Innovations that uses big data analyses to detect deviations in production processes.

Trend-setting impulses: for 35 years, Bosch Rexroth has shaped the development of controlled tightening technology.

As a key user, Rexroth also applies its expertise to Industry 4.0. Because the Nexo has a fully integrated control unit, it fits into production hall networks without any additional hardware and communicates directly with the line control and archive server. The web-based software provides location-independent access to the data – whether from a PC or smart device. Thanks to its integrated barcode scanner, the cordless nutrunner can also identify the corresponding parts and accurately guide the worker through the assembly process. If the wireless connection ever is lost, the device temporarily stores the tightening results data in a data buffer and transmits it automatically once the connection has been reestablished. With decentralized intelligence, connectivity, integrated data collection and targeted process control down to batch size 1, the Nexo cordless nutrunner fulfills all Industry 4.0 criteria.

In compliance with the obligatory monitoring and documentation for safety-critical tightening connections, the torque and angle of rotation must be measured directly on the nutrunner; this can be achieved by means of angle of turn and torque sensors, for example. An indirect measurement via the current used is insufficient. For each tightening process, the extensive sensor system of the Nexo generates up to four DIN A4 pages of data, which is made available in the open-source JSON format (JavaScript Object Notation). The process manager receives an exact graph for quick analysis of each tightening case. By comparing this with the optimal process, far more assembly errors can be detected than is stipulated in the legal framework. In battery assembly, for example, an incorrect cable can be detected when tightening the cable clamp due to predefined parameters in the tightening program. Incorrect bolts and missing or double washers are further examples.

Efficient introduction and changeover: as a scalable, comprehensive solution with integrated intelligence, the Nexo cordless nutrunner fits into existing IT systems.

The size of the database also determines how effective a fault prevention strategy actually is and how effectively expensive rework can be prevented. Ultimately, battery assembly follows a precisely-defined sequence, whereby no tightening connection can be missing or faulty. In order to control the number of tightening connections in the process and immediately identify NOK connections (not OK), a separate program can be created for each tightening case, which is in turn divided into up to 12 steps – including loosening and retightening. The worker receives precise guidance, in conjunction with a display terminal and a localization solution. For example, a blue point on the monitor shows the next tightening position; once this has been successfully tightened, it turns green. Interrupting the tightening sequence is also possible. The corresponding tightening position is saved and displayed for the worker once the task is resumed. If the nutrunner is not in the correct position, it does not receive approval. A corresponding nutrunner localization can take place using triangulation between the transmitter and receiver, by means of camera technology, ultrasound or a combination of the two. With stationary systems, the nutrunner can be precisely located to within 10 mm.

With intelligent, complete systems for reliable tightening, automobile manufacturers, suppliers and service providers can effectively protect the health of their workers, increase productivity beyond obligatory monitoring and documentation, and safeguard and optimize process quality for the long term. Furthermore, the complex assembly sequences of battery packs for electric mobility can be designed so that they not only conform to standards but are also efficient and fault free.