CytroConnect helps prevent unexpected equipment failures by continuously monitoring the health of hydraulic systems. It collects real-time data on things like pressure, temperature, and flow rate. By analyzing this data, it can detect early signs of wear or malfunction, allowing maintenance teams to address potential issues before they cause a breakdown.

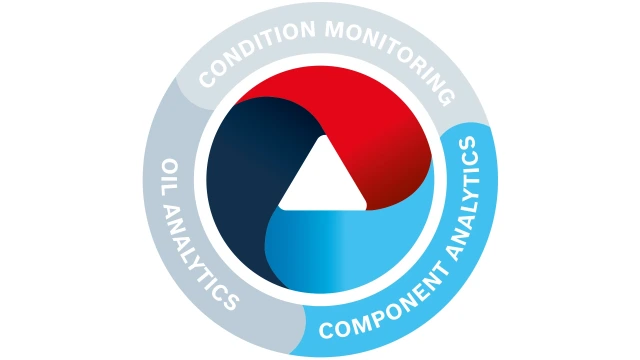

Enhance uptime and efficiency with our intelligent predictive maintenance platform, designed to empower service teams at all levels by preventing issues before they arise. Optimize your manufacturing processes by integrating IoT technology, predictive analytics and cloud-based services.

FAQ to the CytroConnect Solutions

How does CytroConnect help prevent unexpected equipment failures?

Is CytroConnect compatible with all types of hydraulic systems?

CytroConnect is designed to work with a wide range of hydraulic systems, but it may require specific sensors or adaptors depending on the system's design. While it’s highly adaptable, it’s best to confirm compatibility with your specific equipment before installation to ensure smooth integration.

How secure is my data with CytroConnect?

Data security is a priority with CytroConnect. The system uses encryption and secure communication protocols to ensure that all your data remains private and protected from unauthorized access.

Can CytroConnect be used remotely?

Yes, CytroConnect can be used remotely. It allows users to access the system's data and perform monitoring from virtually anywhere, using a secure internet connection.

Can CytroConnect be integrated with existing monitoring systems?

Yes, CytroConnect can typically be integrated with existing monitoring systems. It is designed to work alongside your current setup, so you don’t have to replace your whole infrastructure.