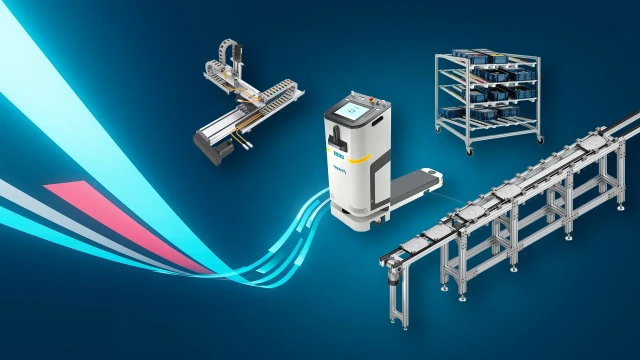

Forging ahead on the fast track: Clever solutions for industrial automation.

Taking your battery production to a new level

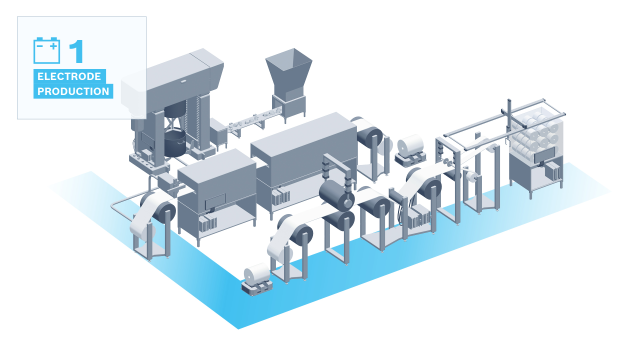

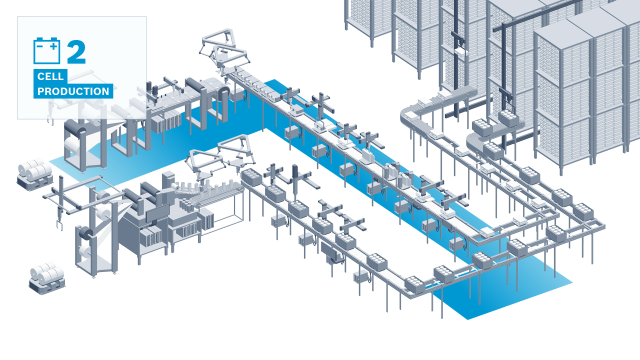

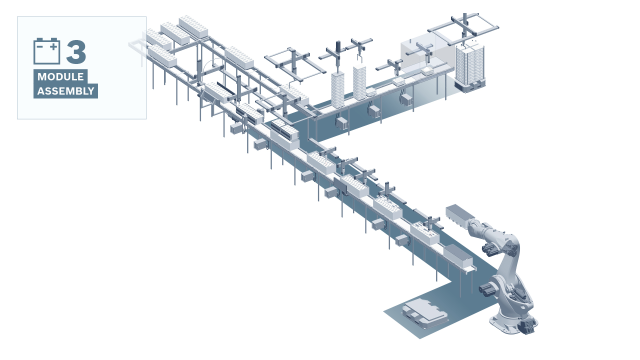

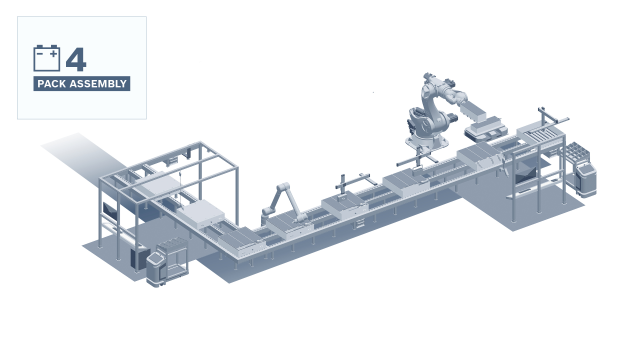

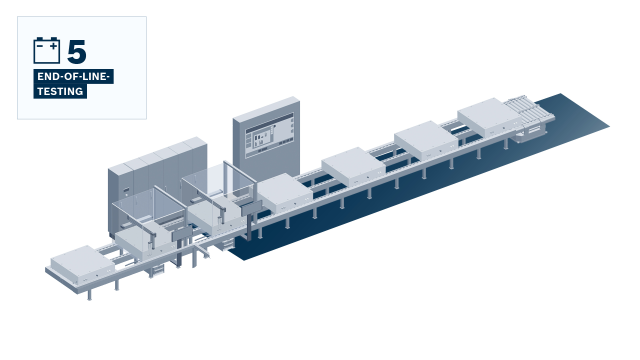

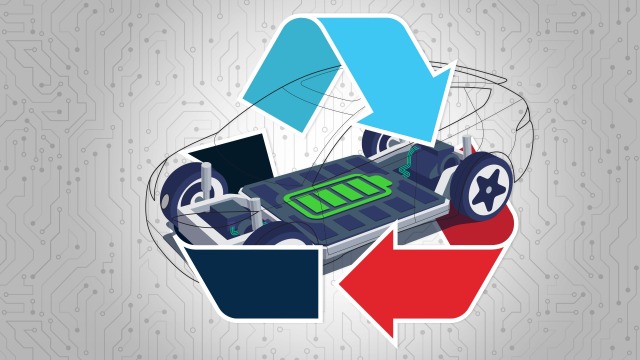

Battery production requirements are in constant flux. The battery manufacturing process must become more flexible, transparent and intelligent. Bosch Rexroth delivers innovations that give you the flexibility and speed you need for tomorrow. All components, modules and system solutions from Bosch Rexroth are based on open interfaces and are designed for optimum connectivity. This means: reducing the complexity of automation projects and increasing overall productivity and availability. At the same time, flexible expansion options allow broad scope for action.

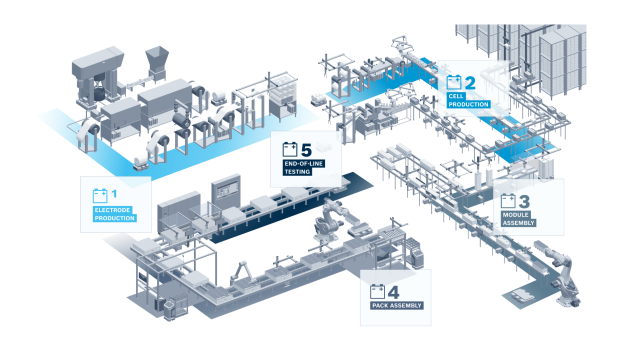

Your partner for the entire value stream

Contact us

Nobody knows our technologies better than we do. That's why we will find the right solution for your battery manufacturing of the future in record time.