Hydraulic solutions for greater sustainability

Our solutions for the hydrogen industry

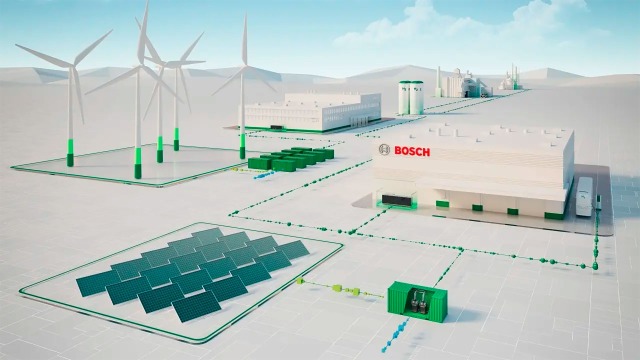

Green hydrogen from renewable energies is a key component in achieving global climate targets. It is a convincing alternative to fossil fuels, particularly in heavy goods transportation. As with electromobility, a nationwide infrastructure is crucial for success. Hydrogen must be stored and transported under high pressure or in frozen, liquid form – refueling must be efficient, safe and as fast as possible.

Bosch Rexroth contributes decades of experience in industrial hydraulics and offers customized, innovative solutions for the compression of liquid and gaseous hydrogen – from robust, safe components to engineering support and complete servo-hydraulic, turnkey solutions.

Bosch Rexroth & Maximator Hydrogen: Innovative solutions for H2 refueling stations

Together with the company Maximator Hydrogen, Bosch Rexroth has developed a solution for efficiently compressing hydrogen in hydrogen refueling stations. With an energy-efficient drive and automatic seal changing, Maximator Hydrogen has raised the efficiency of its innovative Max Compression 2.0 compressor to an entirely new level.

Speed up construction and commissioning: Virtual engineering from Bosch Rexroth

New machine concepts and customer-specific solutions need to be rolled out more quickly than ever before. Virtual engineering is the key lever when it comes to achieving a shorter time to market. Bosch Rexroth has supported machine and system manufacturers for more than 30 years with virtual engineering, as a service provider and as a software partner.

Contact us

We have proven technologies and expertise that you can trust. Let us find the right solution for your hydrogen project quickly.

Other H2 solutions and services from Bosch

This is how we are driving the hydrogen economy along the entire value chain.