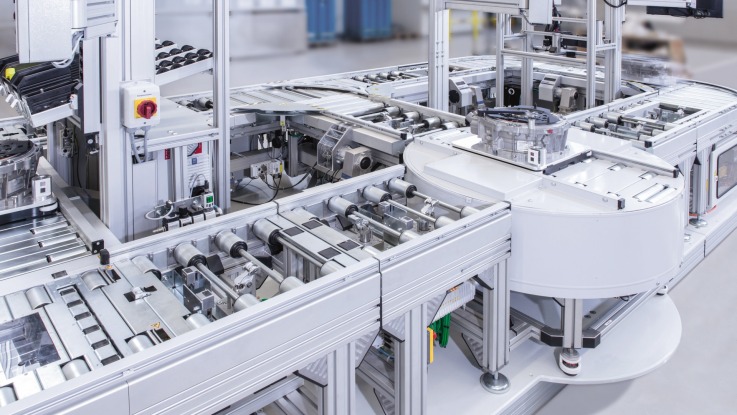

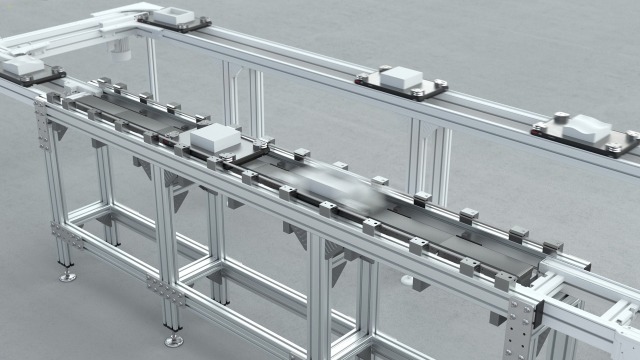

The TS 5 roller conveyor system transports loads up to 400 kg and more, over long distances where necessary. While its robust construction makes it especially suitable for harsh environments. Appropriate for many industries like Energy storage and management, Electronics and home appliances or Automotive, e-Mobility and transportation.

The heavy weight in the Rexroth product transfer system line shines thanks to its tremendous cost-effectiveness and consistent quality. With its king shaft drive, the TS 5 stands out as a rugged pacemaker even in the harshest manufacturing environments – and the greatest possible degrees of freedom for you when it comes to layout planning and use of space. The TS5 roller conveyor can be adjusted even more flexibly to the requirements of the most diverse industries – from the automotive industry, to electro mobility and electronic and household devices. The elite class of roller conveyors offers an efficient and economical solution for every application.

HEAVY LOADS HANDLED FOR MANY INDUSTRIES

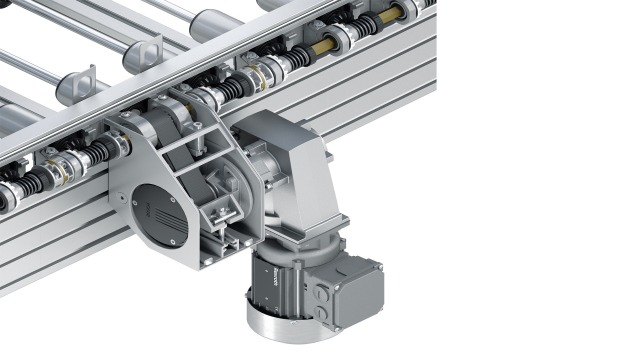

DRIVEN BY HIGH QUALITY TECHNOLOGY

The TS 5 transfer system with king shaft offers considerable advantages compared to usual chain drives.

For example:

- Low maintenance

- Noise-free operation

- High energy efficiency through effective performance with low drive force requirements

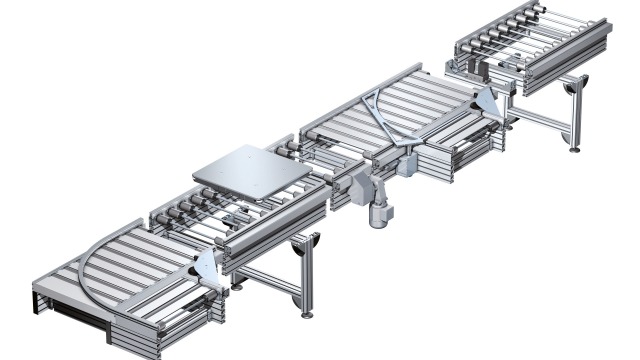

MODULAR CONCEPT

The TS 5 transfer system has its sights set squarely on the future. Equipped with modern components and even more practical features, it can be easily integrated into the newly digital world of production. Enhanced with numerous modules that offer a high degree of customizing possibilities and a thoughtful modular design principle, the innovative transfer system offers you more freedom than ever in system design and construction.

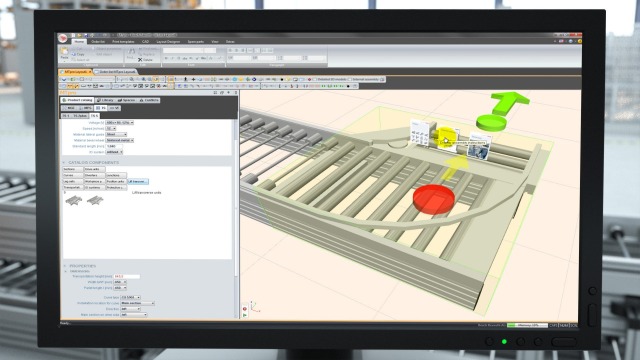

SIMPLE AND FAST PLANNING

The engineering Software MTpro offers you a flexible and simple layout planning. Intuitive design with high degree of planning confidence. Saves time and money in the procurement process. As the components of TS 5 are included in MTpro, the parts list is generated automatically, which considerably simplifies the entire planning process.

Key technical data

| Workpiece pallet weight: |

> 400 kg, max. 50 kg per roller |

| Workpiece pallet sizes: | 455 x 455 up to 1,040 x 845 mm |

| Roller dimension: | 60 mm |

| Roller spacing: | 130, 195, 260, 325 mm |

| Environments: | Approved for Class 8 cleanrooms in accordance with DIN EN ISO 14644-1 |

| Order Information |

Special components

| King shaft drive: |

Low-maintenance, energy-efficient and low noise drive concept |

| "Open Center": | Open conveyor section for easy access to the workpiece from below |

| Three-way diverter: | T-shaped outfeed with three options: right, left, up or down |

| Rotation unit: | Performs the function of a diverter, junction and crossing in one unit, rotation angle from 45° up to 180° |

| Positioning unit: | Absolute precision (+/- 0.3 mm) through accurate positioning of workpieces at processing stations |

| Drive unit: | Powerful drive unit incl. conveyor section with flexible configuration options |

| Lift transverse unit: | Easy to transport workpieces in the transverse section with a stroke of 4.5 mm |

| Drive kit: | Drive kit as separate, self-contained module with conveyor section which can be placed at the beginning or end face of the conveyor |

| Swing gate: | Mobile swing gate for flexible access in a square |