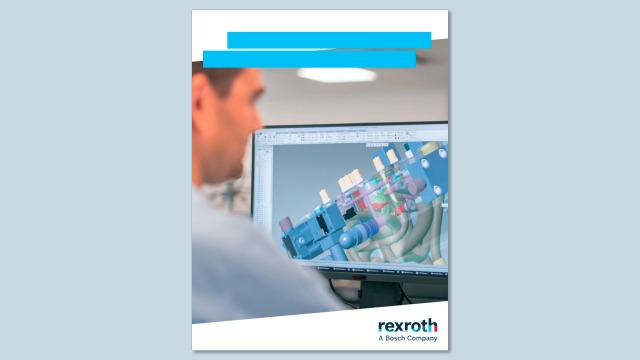

Hand-in-hand: Design and simulation included

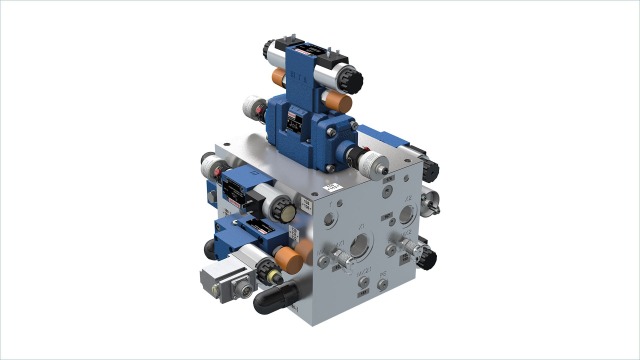

As manifold supplier, we make use of state-of-the-art procedures to design your hydraulic manifold. We also optimize space and channel geometries for minimum energy losses and guaranteed functional safety through stability and flow analysis simulations.

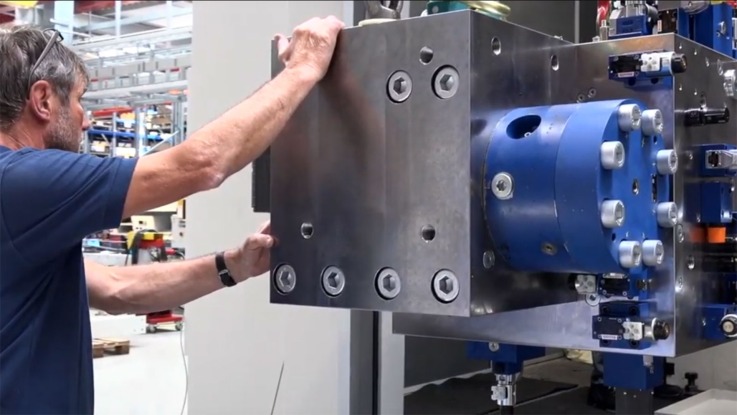

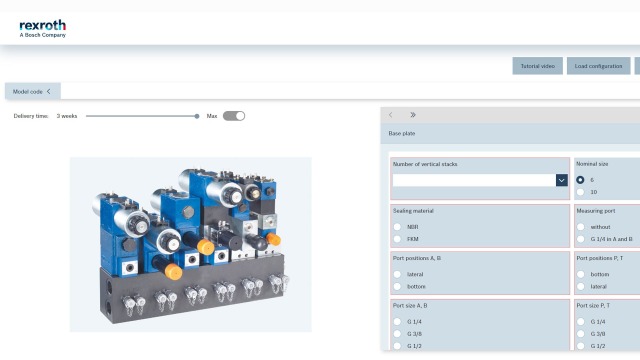

Processing based on the design data

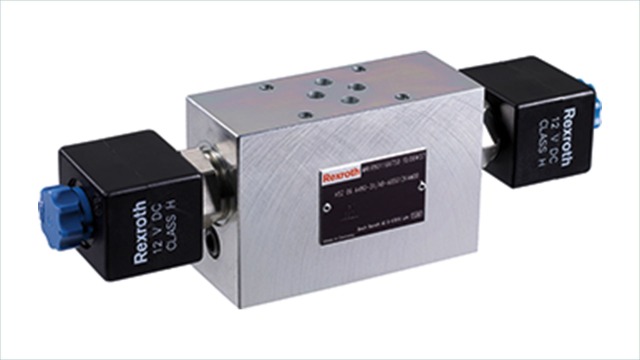

We process hydraulic manifolds from low-pressure to high-pressure versions using high-precision CNC processing centers only. We derive the processing steps directly from the design data. That way, we can reliably prevent errors and ensure safety.

An important side-effect of CNC machining: We monitor the execution of each individual work step, measure the execution, and compare this with the design data. You can therefore be sure: We implement your approved CAD data one-to-one, so that your individual manifold seamlessly fits into your design.

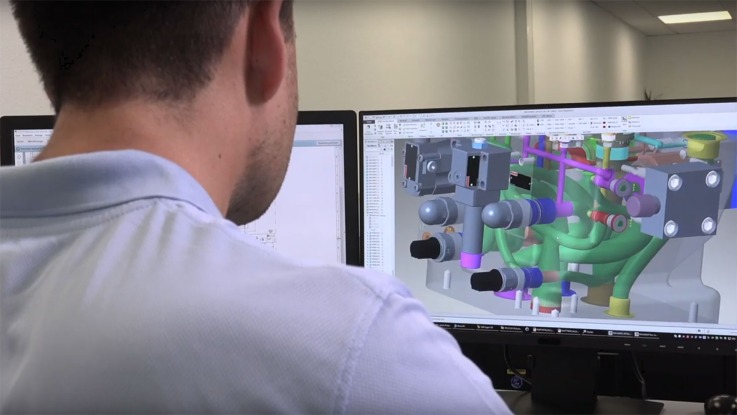

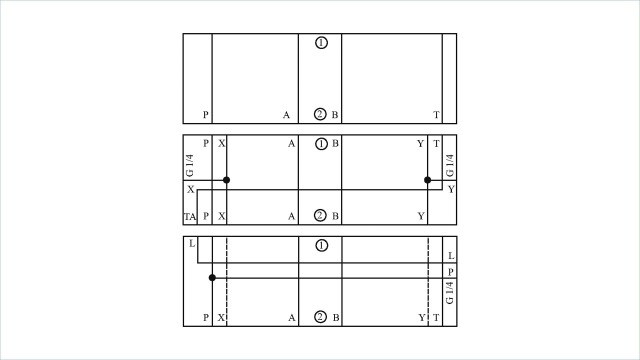

The digital twin for your valve block

A virtual image of your manifold is made available to you – the requirement for a digital twin. This way you are one further step towards Industry 4.0 and the Internet of Things. You virtually integrate the hydraulic manifold into your individual construction and are thus able to proceed to work on your project while we are manufacturing the manifold. This saves time and reduces the time-to-market. What’s more: You fulfill customer requirements for digital images of your machinery and equipment.