Secondary control solutions from Rexroth

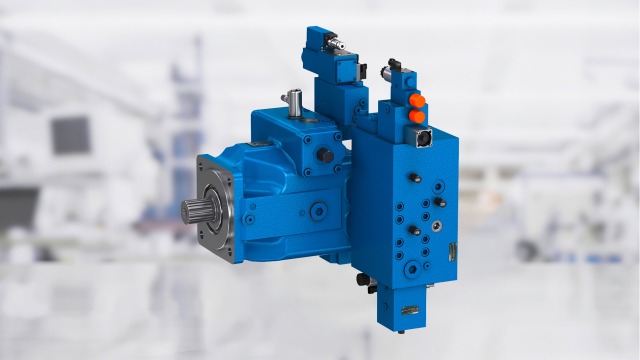

The expectations of system solutions are higher today than ever before. High performance, low energy consumption, high dynamics and outstanding controllability are just some of the properties a modern drive strategy must exhibit. Secondary-controlled drives from Bosch Rexroth combine high dynamics with control accuracy and energy recovery.

Discover the advantages:

- High level of reliability and availability

- High dynamism of speed and torque

- High precision and easy operation

- Possibility of storing and recovering energy

- Parallel operation of different consumers without constraints

- Minimal installation space required

- Flexible systems, especially concerning safety functions

Applications

| Machine construction | Marine & offshore | Test benches | Material handling and transport |

|---|---|---|---|

|

|

|

|

References

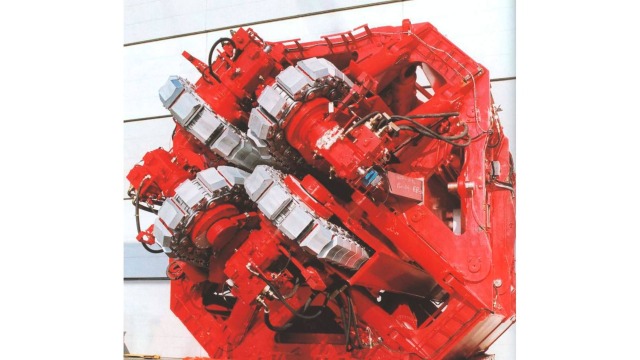

Forging Manipulator

Secondary controlled drive system

- Installed power 2 x 90 kW

- Weight of vehicle 70 t

- Weight of forging 20 t

- Energy recovery in the braking mode

Manufacturer: Diango & Diementhal, Germany

Revolving Stage

Secondary controlled drive system

- Power supply integrated in a hydraulic ring main system 3 x 45 kW

- 1 x secondary unit A4VSO250DS2

Operator: The State Opera Prague

Subsea Crawler Deepsea Mining

Secondary controlled chain drive.

- Operation depth 200 m

- Weight of vehicle 280 t

- Excellent track control

Operator: De Beers, South Africa

Linear Cable Engine LCE

Secondary controlled traction winch.

- 2* A4VSG 125 DS2 tandem units

- High dynamic speed and torque control

- 640 kW installed power

Manufacturer: Dynacon, USA

Mobile Crane SGC 140

Follow up project due to the excellent handling of the first mobile crane with secondary control 2010.

- Boom length up to 130 m

- Ring diameter slewing device = 50 m

- 2820 t Payload

- 4.000 t Counter weight

Manufacturer: Sarens, Belgium

Special Handling System SHS

The SHS is used for the installation and recovery of sub sea gas production modules in an operation depth down to 320 m.

- 40 * A4VSG355DS2

- 420 t Safe working load

- Installed power 3,5 MW

- Crane height 35 m

Manufacturer: AXTech, Norway

Rineer Test Bench

Load Test Bench for three test axes for the testing of Rineer vane motors up to series 125 with 4096 cm3 displacement.

- 1* A4VSO750DS1 tandem unit

- 1* A4VSO125DS1 tandem unit

- Installed power: 520 KW

Test Bench Operator: DC USA

Knuckle Boom Crane

The main winch and the auxiliary winch use the same pressure controlled primary station and reduce the installed power.

- 135t AHC Crane

- 13 t AHC Auxiliary Winch

- Integrated AOPS and MOPS Function

- Integrated Anti Slack Protection

Crane Manufacturer: TTS, Norway

Mobile Crane SGC 120

The operation radius can range up to 130 m. At 100 m operation radius loads can be lifted > 600 t.

- Secondary controlled lifting and slewing device

- Boom length up to 220m (up to 180m height)

- Ring diameter slewing device = 40 m

- 3200 t payload

- 20 m/min lifting speed

Manufacturer: Sarens, Belgium

Driverless container transport system AGV

Secondary controlled drive, automated transport operation, position determination via sensors in the road bed. High positioning accuracy.

- Load capacity: 50t

- Power: 275 kW

- Speed: 25 km/h

Manufacturer: Kamag, Germany

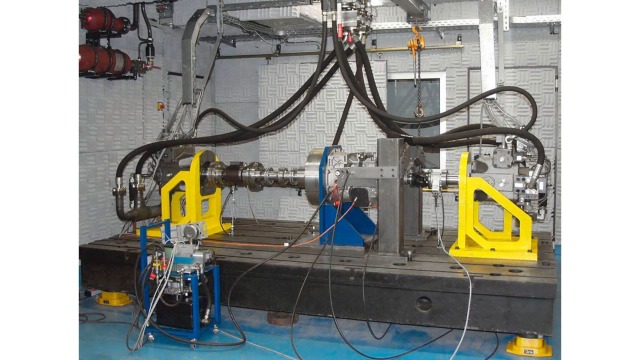

Torsional load test bench RWTH Aachen

Dynamic coupling test bench, consideration of the torsion angle of both coupling halves, energy recovery via the load unit.

- Feed-forward control

- Torsion angle measurement

- Energy recovery

Operator: Institute for Machine Elements (IME) Aachen, Germany

Highly dynamic real crash test bench

The required acceleration power of 530 kW can be lowered to only 30 kW primary power due to the use of hydraulic accumulators.

- Energy recovery

- Power reduction

- Rotational speed difference < 0.3 km/h

Operator: Autoliv, Sweden

Driverless container transporter CT60

More than 200 vehicles in use at the container terminals in Rotterdam and Hamburg. Position determination via sensors in the road bed.

- Load capacity: 60t

- Positioning accuracy < 1cm

- High speed accuracy irrespective of loading

Manufacturer: Gottwald, Germany

Centrifugal force – simulation test bench

For 3000 kW acceleration power only 800 kW primary power required. Up to 60% of the energy is recovered.

- Moment of inertia 35000 kgm2

- 24 * A4VSO250DS1 units

- 30 times acceleration due to gravity attainable

Operator: Framatome, France

Telecommunication cable-laying ship

The ship pulls a plough, opens the sea bed, lays the cable in and closes the trench. The high dynamic of the secondary controlled system prevents the break away of the plough rope while get stuck.

- Down to 1500 m water depth

- 4 * 355 A4VSO

- 130 t load capacity

Manufacturer: Odim, Norway

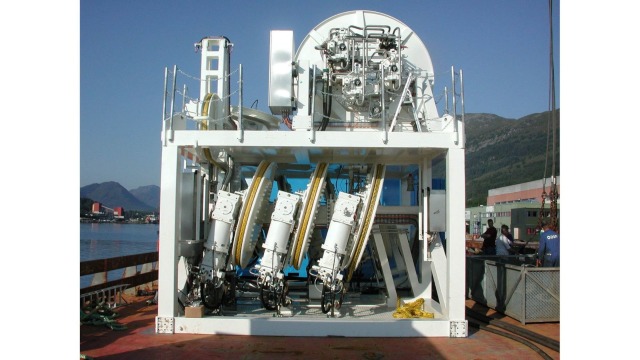

Tensioner drive of a pipeline-laying system

Up to 16” rigid or flexible pipelines are lowered to a depth of 2500 m with the help of two series-connected tensioners.

- Load capacity: 2 * 275 t

- Laying depth up to 2500m

- Laying of pipelines up to 16”

Manufacturer: Huisman, Netherlands

Active heave compensation

Secondary controlled drives work together with conventional hydrostatic drives in a single system. While the conventional hydrostatic drive carries out the lifting function, the superposed secondary controlled drives perform the active heave compensation.

- Compensation value > 90%

- Load capacity 160t

- Working depth of up to 2100 m

Manufacturer: Kenz, Netherlands

Deep sea winch

Conventional winch systems with their heavy steel ropes reach their limits at depths greater than 2500 m. Synthetic fibre ropes, however, are lighter, although more difficult to handle due to their stretching. With the aid of six secondary controlled drives this problem has been solved successfully for the first time.

- Synthetic fibre rope

- Loading capacity 50 t

- Working depth > 2500 m

Manufacturer: Odim, Norway

Crane drive for oil tank platform

Both mounted cranes are used for transferring relief supplies on and off cargo ships. Without the active heave compensation loading and unloading would be impossible. The hoist gear is solely secondary controlled. The slewing gear is also secondary controlled but is additionally supported by a conventional hydraulic rotating drive.

- Active heave compensation with overload protection

- Load capacity 5 t

- Lifting speed 100 m/min

Manufacturer: Sevan Marine, Norway

Underwater robot winch drive

The secondary controlled winch drive lowers the supply unit with the underwater robot (ROV). In active heave compensation mode the ROV undocks and can be remotely controlled for maintenance or monitoring operations.

- Active heave compensation with energy recovery

- Load capacity 20 t

- Lifting speed 140 m/min

Manufacturer: Odim, Norway

Bow thruster for towboats

The integration into an existing hydraulic supply system on board is a cost-effective alternative to conventional bow thruster systems. The power limitation of the secondary controlled drive allows maximum utilization of the primary station.

- 300 kW bow thruster

- Retrofit project with integration into an existing hydraulic system

- Independent parallel operation with other drive systems on board

Manufacturer: Rosetti Marino, Italy

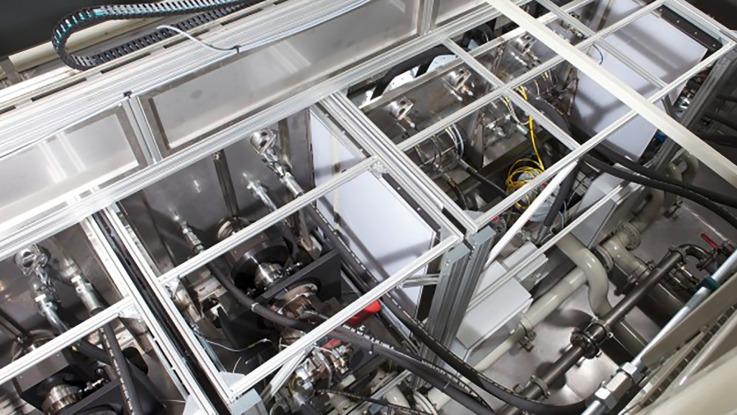

Universal Hydraulic Test Bench

The test bench can be operated at 160 kW from both drive and load sides. The variety of configuration possibilities enables a multitude of tests to be carried out, ranging from component tests right through to efficiency measurement tests of complete systems.

- 160 kW installed power

- Energy recovery of up to 60%

- Flexible configuration allows different test possibilities

Operator: Internationale Hydraulik Akademie, Germany

Rail Milling Machine

The rail milling machine will be used for the maintenance reprofilinig of rails. For this the complete rail milling machine must be driven in speed synchronisation.

- Secondary controlled drive of two milling wagons

- Synchronisation of 4 chassis with 8 secondary controlled units

- Traction control over 66 m train length with 300 t total weight

- At 0,3 – 2 km/h from 0,3 up to 10 mm milling depth

Manufacturer: MFL Liezen Austria