How can 1,000 sensor variants be economically produced on a single line? In small quantities and with minimal engineering effort? For typical pressing and joining processes in assembly, manufacturer Sensata has found a pioneering do-it-yourself solution: the Smart Function Kit Pressing from Bosch Rexroth. How does it work? It’s simple!

When Jean-Marc Hubsch visited the Hannover Messe trade fair, he had something very specific in mind: A modular pre-configured kit for pressing operations that can be quickly assembled, set up and commissioned. Hubsch is Engineering Manager in the Industrial Encoders division at the international sensor manufacturer Sensata. The solution he was looking for in Hanover should not only be able to provide several thousand variants of rotary encoders for autonomously moving transport shuttles with highly precise housing covers. It should also be modular and flexible and allow quick implementation without outside help.

A versatile subsystem which can easily be integrated: the Smart Function Kit with an electromechanical cylinder, a force sensor, a motor, a regulator, a control system and a software package.

Hubsch found the perfect solution at the Bosch Rexroth stand: the Smart Function Kit for pressing and joining applications matched his requirements exactly. This innovative approach combines proven Rexroth standard components such as the EMC electromechanical cylinder, a force sensor, a servo motor, a drive controller and an industrial PC with intuitive HMI software for simple visual programming.

Graphical programming instead of tedious coding

Hubsch and his team strive to simplify as many manufacturing processes as possible– preferably with standard components and without time-consuming programming. To set up the Smart Function Kit Pressing, however, Sensata’s engineers only needed to drag and drop predefined software blocks together to form a workflow and enter the parameters for the individual process steps. A wizard guided through the commissioning, the drive controller parameterized itself automatically. All in all, engineering can be carried out up to 95 percent faster this way!

Plug & Produce: the preconfigured components in the Smart Function Kit for pressing tasks can be put together and set up via drag and drop, just like when building a model.

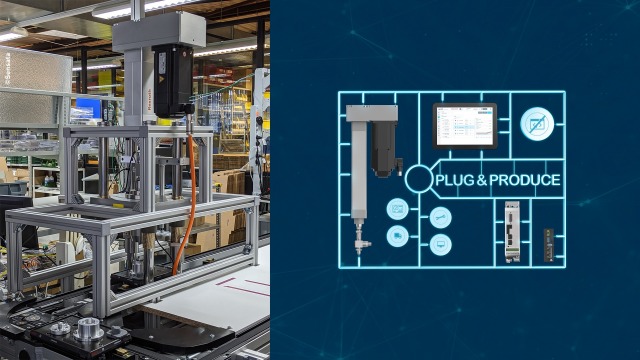

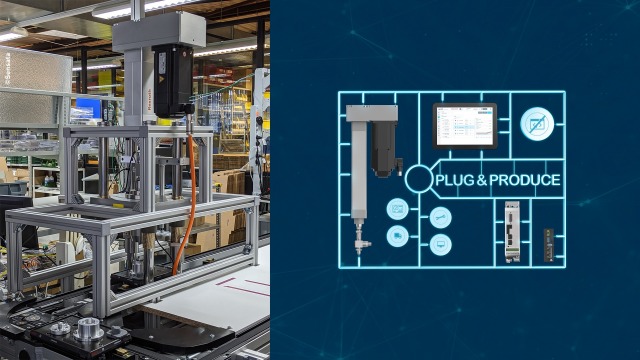

Production of different types of rotary encoders at Sensata: the Smart Function Kit for pressing tasks reduces engineering, commissioning and quality assurance costs. (Copyright: Sensata)

Intuitive tools for transparent manufacturing

The Smart Function Kit Pressing also saves time and money during operation through simple analysis of the pressing process with validation elements. Ready-to-use monitoring functions show live status information and process results including force-displacement curve and allow the data to flow directly into the IT system for quality assurance. This means much greater transparency!

In the new multi-product line for rotary encoders, the Smart Function Kit from Bosch Rexroth presses in the housing flange with an accuracy of +/-0.02 mm. And with a force of up to 800 daN! The pressing force required depends on the variant. Hubsch believes that up to 10,000 of these encoders could be produced economically on such a multi-product line. In the future, the respective production parameters are to be transferred directly to the Smart Function Kit via RFID.

What else Jean-Marc Hubsch likes about the Smart Function Kit: It was simply designed in advance and then ordered online. To further simplify engineering, he also purchased the TS 2plus transfer system, also of modular design, and the XM21 automation platform as a common control system from a single source. Hubsch sees the complete multi-product line as a proven blueprint for further production sites. “With the help of Bosch Rexroth’s global support, the solution will be internationally scaled and will continue to grow step by step,“ says Hubsch.

Versatile all-rounder: the modular TS 2plus transfer system performs a wide range of transport tasks with standardized modules.

For more information about the Smart Function Kit Pressing click here.