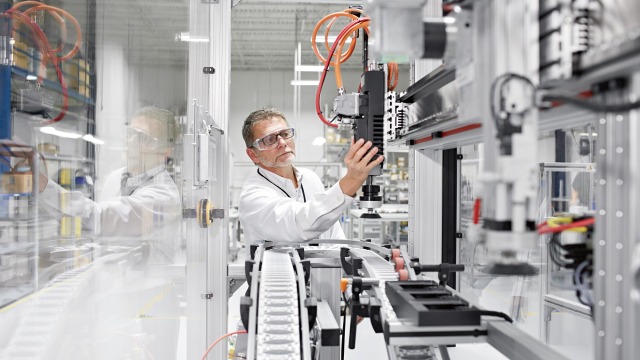

Technical jobs

Do you enjoy using not only your brain, but also your hands? Do you like solving tricky problems and are you good at visualizing complex processes? Perfect! A technical training program provides the ideal opportunity to develop your talents further.

We have a long tradition of providing top-quality training: Our trainees are generally among the best in their CCI year group. Above all, however, with us, you will see just how much fun "the serious side of life" can be.

Our apprenticeships

Electronics technician for devices and systems (f/m/div.)

Your responsibilities

- Creating new things: producing information and communication technology devices

- Helping to shape the future: developing customer-specific solutions as a team

- Following a holistic approach: handling orders independently

- Networked communication: using new media as a tool for implementing collaborative projects

Your profile

- Personality: sense of responsibility and a team spirit

- Way of working: in a structured and forward-looking manner

- Qualifications: good grades in science subjects, secondary school leaving certificate desirable

- Interests: solving complex problems and understanding technical relationships

Useful information

- Duration of training: 3.5 years

- Application to be submitted: one year before the start of training

- Opportunities for development and promotion as a foreman, technician, and Bachelor of Engineering (B. Eng.)

- Emphasis on learning by doing and working as part of a team. The accompanying lessons at the vocational school in Lohr am Main ensure a secure grasp of the theoretical side of things.

Specialist for metals technology in the field of assembly technology (f/m/div.)

Your responsibilities

- You will be responsible for inspecting, maintaining, repairing, and assembling tools, machines, devices, and apparatus.

- You will read technical drawings and mold sheet metal, plates, and tubes into the desired shape.

- Care and maintenance of devices.

Foundry mechanic (f/m/div.)

Your responsibilities

- Creating new things: pouring new castings on a daily basis

- Helping to shape the future: producing prototypes using 3D printers

- Taking on responsibility: ensuring the highest quality

- Using creativity and freedom: thinking freely, unconstrained by problems

- Acting reliably: implementing work specifications independently

Your profile

- Personality: reliable, good with your hands, physically fit

- Way of working: as part of a team

- Qualifications: qualifying secondary school certificate, good spatial awareness

- Interests: interest in technical processes in the foundry, interest in physics and chemistry

Useful information

- Duration of training: 3.5 years

- Application to be submitted: one year before the start of training

- Emphasis on learning by doing and working as part of a team. The accompanying lessons at the vocational school in Pegnitz ensure a secure grasp of the theoretical side of things.

Industrial electrician for devices and systems (f/m/div.)

Your responsibilities

- Creating new things: handling the production, commissioning, and testing of electrical equipment and systems

- Helping to shape the future: optimizing automated production equipment

- Following a holistic approach: handling orders independently

- Thinking holistically: working efficiently with upstream and downstream production areas

Your profile

- Personality: sense of responsibility and a team spirit

- Way of working: in a structured and forward-looking manner

- Qualifications: good grades in science subjects; qualifying secondary school certificate

- Interests: solving complex problems and understanding technical relationships

Useful information

- Duration of training: 2 years

- Application to be submitted: one year before the start of training

- Opportunities for development and promotion as a foreman, technician, and Bachelor of Engineering (B. Eng.)

- Emphasis on learning by doing and working as part of a team. The accompanying lessons at the vocational school in Lohr am Main ensure a secure grasp of the theoretical side of things.

Industrial mechanic (f/m/div.)

Your responsibilities

- Creating new things: setting up production plants and tools

- Helping to shape the future: programming data for processing workpieces and for controlling the production process

- Taking on responsibility: ensuring the highest quality

- Acting reliably: implementing work specifications independently

Your profile

- Personality: reliable, good with your hands, physically fit

- Way of working: systematic approach, working as part of a team

- Qualifications: qualifying secondary school certificate or secondary school leaving certificate

- Interests: passion for technology

Useful information

- Duration of training: 3.5 years

- Application to be submitted: one year before the start of training

- Opportunities for development and promotion: engineer, technician, foreman

- Industrial mechanics follow procedure documentation to assemble components into assemblies and assemblies into machines. To do so, they process components both mechanically and manually.

- They monitor the production process and identify and rectify errors and defects. They also inspect the quality of the products produced.

Machine and plant operator (f/m/div.)

Your responsibilities

- Creating new things: producing sheet metal casing and components in a wide variety of shapes and forms

- Helping to shape the future: operating and programming Rexroth-controlled sheet metal processing machines

- Taking on responsibility: ensuring the highest quality, controlling and monitoring process flows and carrying out production control

- Acting reliably: implementing work specifications independently

Mechatronics engineer (f/m/div.)

Your responsibilities

Creating new things: producing equipment and products in the field of hydraulics, pneumatics, mechanics, electrical and control engineering

Helping to shape the future: developing new machines and products and modifying or optimizing existing systems

Acting reliably: working to a high standard with high value components and showing responsibility for safety

Thinking holistically: eliminating faults on mechatronic systems; programming and modifying processes

Your profile

- Qualifications: secondary school leaving certificate desirable and advisable; good grasp of technical concepts, good foundation in math and physics, good command of English

- Way of working: conscientious, focused, logical thinker, team player, organized, independent, open to new things

- Interests: the most important thing is to have a healthy motivation. The training is very varied, fast-paced and demanding, just as the subsequent working environment will be.

Useful information

- Duration of training: 3.5 years

- Application to be submitted: one year before the start of training

- Emphasis on learning by doing and working as part of a team. The accompanying lessons at the vocational school in Lohr am Main ensure a secure grasp of the theoretical side of things.

Technical product designer (f/m/div.)

Your responsibilities

- Taking on responsibility: from the outset, modelling 3D-models of components from which standard-compliant drawings and parts lists are created.

- Acting reliably: before a device, technical system, or machine can be manufactured, a precise model must be produced from which accurate drawings are created. Technical product designers (f/m/div.) produce these construction manuals exactly according to the specifications of engineers or designers.

Technical modeler (f/m/div.)

Your responsibilities

- Creating new things: producing models for new parts

- Helping to shape the future: operating CNC machine tools and 3D printers

- Acting reliably: meeting customers’ requirements

- Demonstrating cooperation: coordinating with the upstream and downstream areas

Cutting machine operator (f/m/div.)

Your responsibilities

- Creating new things: producing turned and milled parts on conventional and computer-controlled machine tools

- Taking on responsibility: ensuring the highest quality

- Acting reliably: taking responsibility for technical communication and maintenance

Your profile

- Qualifications: qualifying secondary school certificate is required, secondary school leaving certificate desirable and advisable; grasp of technical concepts, good foundation math and physics, good command of English

- Way of working: conscientious, focused, logical thinker, team player, organized, independent, open to new things

- Interests: the most important thing is to have a healthy motivation. The training is very varied, fast-paced and demanding, just as the subsequent working environment will be.

Useful information

- Duration of training: 3.5 years

- Application to be submitted: one year before the start of training

- Emphasis on learning by doing and working as part of a team. The accompanying lessons at the vocational school in Lohr am Main ensure a secure grasp of the theoretical side of things.

Materials tester (f/m/div.)

Your responsibilities

- Independent planning, implementation, and monitoring of work processes.

- Measuring and checking lengths, shapes, angles, and physical quantities.

- Evaluating and documenting processes and measured values.

- Configuring and monitoring automated processes.

Training at Bosch Rexroth

Shape your future. It starts now.