Hydraulic solutions for greater sustainability

Our solutions for the hydrogen industry

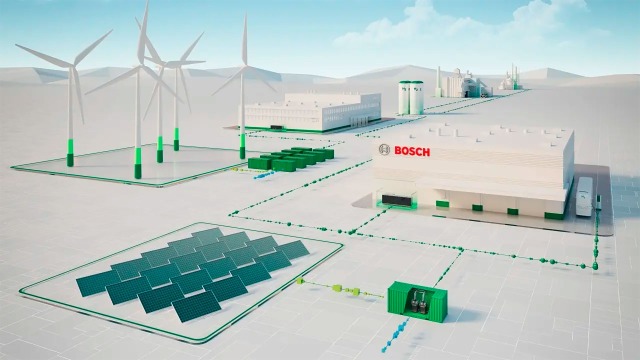

Green hydrogen from renewable energies is a key component in achieving global climate targets. It is a convincing alternative to fossil fuels, particularly in heavy goods transportation. As with electromobility, a nationwide infrastructure is crucial for success. Hydrogen must be stored and transported under high pressure or in frozen, liquid form – refueling must be efficient, safe and as fast as possible.

Bosch Rexroth contributes decades of experience in industrial hydraulics and offers customized, innovative solutions for the compression of liquid and gaseous hydrogen – from robust, safe components to engineering support and complete servo-hydraulic, turnkey solutions.

Press Release Center

Read the latest news about Hydrogen solutions from Bosch Rexroth

Contact us

We have proven technologies and expertise that you can trust. Let us find the right solution for your hydrogen project quickly.