Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

- Civil Engineering

- CPG

- Building Automation

- Warehouse Automation

- Aerospace

- Mining and Minerals

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview- Home

- Products

- Product groups

- Assembly Technology

- Manual Production Systems

Redesigned frontend creates even more digital transparency for sustainable improvement in production and is even easier to use.

Compared to current LED system lamps, they are 50% brighter and use 20% less energy.

And require half the investment thanks to the innovative tri-light configuration.

Find the right solutions for your manual or semi automated lines.

SHAPE YOUR LEAN SHOPFLOOR

with Rexroth Manual Production Systems

The main concern of modern production is to avoid waste. The MPS Manual Production Systems from Rexroth have been developed strictly in line with aspects for lean production, enabling simple and fast planning and implementation of lean production installations.

The demands on modern, lean production are more than just focusing on individual modules. In fact, an integrated system with a uniform implementation concept comes to the forefront. At Rexroth, this concept is reflected by the MPS philosophy.

Design your individual workstation solution

Product Overview Manual Production Systems

Customized workstations

With MPS, you can flexibly design your own individual workstation solution.

Choose from custom products, which enable you to put together the perfect solution using numerous parameters. Or select from standard products with fixed dimensions.

In addition, a comprehensive program of accessories consisting of workstation lighting, power supply, height adjustment, information provision and positioning of tools, as well as ESD components and swivel work chairs, is available.

Your advantages:

- Targeted and optimized use of capacities

- Work with reduced fatigue

- Increased productivity

- Motivated employees

Find out more about the complete portfolio in our PDF-Catalog

Manual linking

Discover the full range of products for your manual processes.

When dealing with numerous variants, customized workstation material shuttles enable you to precommission a material shuttle with the associated parts for each variant.

Logistics material shuttles are used to manually link a supermarket shelf with workstations, to link two workstations or production islands, or to supply workstations with material from a supermarket.

FiFo stations can be compared to a supermarket for floor rollers, material shuttles and commissioning shuttles. The supermarket's size can be adjusted easily and quickly to your individual needs through the modular rail system.

EcoFlow components are used to implement material flow systems at workstations, to link workstations, as well as in the warehouse and commissioning area. EcoFlow eases worker strain because products and workpiece pallets are conveyed on manual slide sections.

Find out more about the complete portfolio in our PDF-Catalog

Material supply

Rexroth material supply and flow rack systems offer a wide range of options for storing and supplying materials and containers, regardless of segment.

Whether commerce, trade or industry: The flow rack systems can be used as a supermarket shelf at a central point or to directly supply containers at the workstation.

Your benefits:

- Economical thanks to various conveyor tracks and rollers

- Universal with customer-specified equipment and dimensions

- Future-proof by easy conversion and expansion

- Clear design thanks to colored rollers in the conveyor tracks (kanban)

- Efficient by incorporation of the FiFo principle

Find out more about the complete portfolio in our PDF-Catalog

Tubular framing

EcoShape: Next dimension in tubular framing systems

The EcoShape tubular framing system literally rounds up the aluminum profile portfolio as it enables easy connections between square and round elements. The T-slot enabled system is fully compatible with the Rexroth’s Aluminum Framing System and Manual Production Systems.

Create individual solutions in a lean way for equipment such as workstations, material shuttles, or flow racks in line with the poka yoke and Kaizen principles.

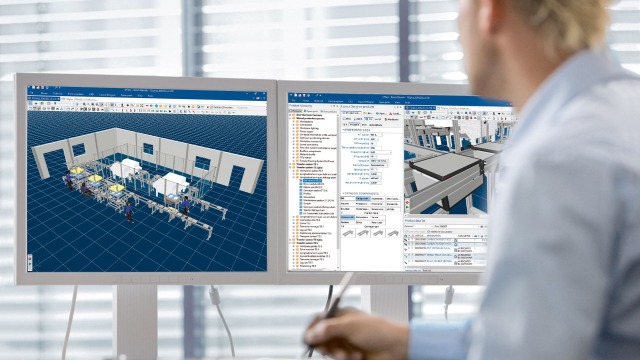

The components for the tubular framing system are included in Rexroth's MTpro planning software and are strikingly easy to cut, to assemble and to handle. This saves time and cost designing and setting up your system.

Key features:

- Connectors can be combined with the EcoShape D28L and D28L, N10 round tubes, as well as the D28 round tube

- Poka yoke system for easy and secure connector installation

- Twist locks for secure joints

- Positive interlocking connection

Swivel chairs

Easily optimize the ergonomic layout of your workstations and enhance physical wellbeing and productivity.

Many people spend the majority of their lives at their workstation – particularly in the production sector. Ergonomics and a healthy posture are important for your staff as they work on production lines, machinery or conveyor belts. A good swivel work chair must provide optimal support to dynamic sitting if it is to promote the health of the people using it. It must be able to be customized to the particular user and the typical movements made while working.

Key features:

- Chair design for all areas of use

- Supports the S shape of the vertebral column, lumbar support

- Encourages dynamic sitting through synchronous techniques and weight regulation

- Extendable control elements for easy adjustment

- Use of environmentally-friendly materials

- Ergonomic accessories

ACTIVE Cockpit

The software solution for your continuous improvement process – supplying and visualizing manufacturing data in real time

As an interactive software solution ACTIVE Cockpit processes and visualizes production data in real time. ACTIVE Cockpit networks IT applications such as production planning, quality data management and e-mailing with the software functionality of machines and plants. The information is the basis for decisions and process improvements.

Your benefits:

- All relevant real-time information is available for everyone at all times

- Intelligent networking saves information processing time

- More efficient improvement processes through clear analysis and conclusive task definition with ACTIVE Cockpit

- Quick and easy to extend with the following apps: Value stream, LeanIndicator, DeviationManager, Diagramm

Learn more about efficient material supply within the Factory of the Future

ACTIVE Shuttle helps increasing the automation of your intralogistics processes and material supply. The ACTIVE Shuttle Management System (AMS) enables highly flexible order management, in which orders can be entered manually or automatically fed via third systems.