Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

- Civil Engineering

- CPG

- Building Automation

- Warehouse Automation

- Aerospace

- Mining and Minerals

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview- Home

- Smart MechatroniX

- Smart Function Kit for pressing and joining applications

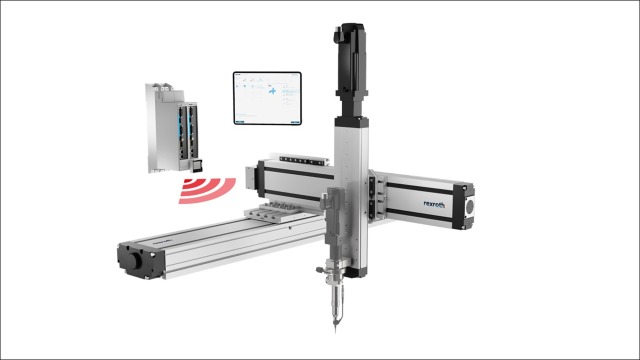

Flexible, compact and future-oriented.

Servo press for multiple standardized joining tasks

Whether it be assembly, joining, forming, measuring or testing – the Smart Function Kit is suitable for many pressing and joining applications with forces up to 70 kN. The modular servo press combines mechanical and electrical Rexroth components with software and is the perfect basis for system integrators or end users with process know-how.

Flexible, compact and future-oriented

You benefit from easy product selection, commissioning, programming and evaluation. Furthermore, the Smart Function Kit can be connected via open interfaces and conveniently monitored on a tablet. This maximizes transparency, reduces downtime and increases the productivity of the electric press.

White Paper: Plug & Produce in Factory Automation, Pressing and Joining

Learn about setting up production modules quickly, automatically putting them into operation and collecting production data at the same time – with the Smart Function Kit for pressing and joining applications.

Fill out a short form and get the white paper instantly in PDF format.

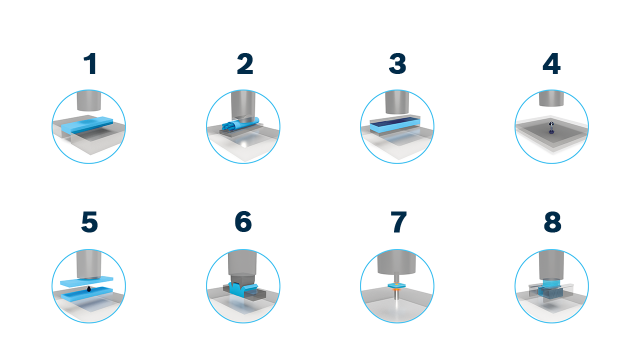

One system – multiple applications

Assembly and joining

- Press-Fitting

- Crimping

- Assembling

- Riveting

- Bonding

- Inserting

- Welding

- Clipping

Forming

- Bending

- Embossing

- Deep Drawing

- Shaping

Testing

- Testing

- Measurement

One mechatronic solution – numerous benefits

Easy product selection

- Pre-selected mechanical and electrical components as well as software are combined in various kits for forces up to 70 kN

- Quick and easy design, selection and configuration with modern e-tools

- All components from a single supplier

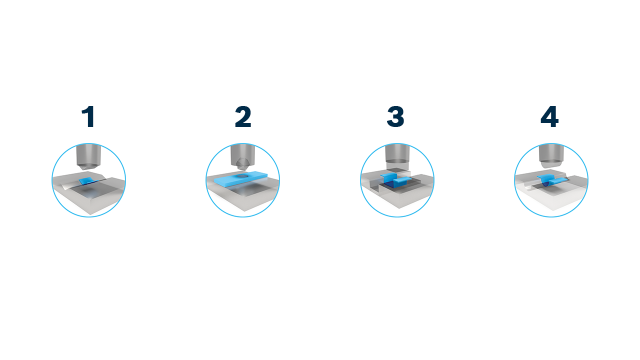

Plug & Produce

- Delivered in a single package, including preinstalled operating software.

- Automatic parameterization of the servo drive.

- Few interfaces: servo drive with integrated motion control.

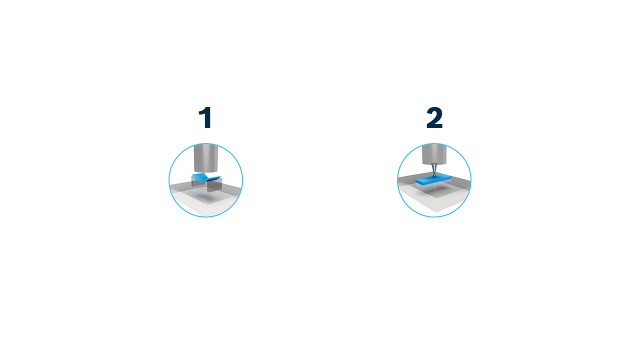

Zero Programming

- No programming knowledge required.

- Simple and logical configuration of the process and the evaluation elements.

- Browser-based HMI, can be used on various end devices.

- Modern and intuitive design.

Fieldbus Function Block EtherNet/IP

Watch "how to" videos or download the example file and get the following:

- SFK for Pressing – Allen Bradley AOI Fieldbus Example Documentation

- SFK for Pressing – Allen Bradley HMI Example Documentation

- Fieldbuss connection via Ethernet/IP, Profinet and Sercos