Better boom control for your mobile elevating work platform

Decentralized Boom Control – DBC

Rexroth’s Decentralized Boom Control (DBC) is a smart control solution for Mobile Elevating Work Platforms (MEWP) that combines Rexroth electro-hydraulics, software, and application know-how into a complete package that reduces complexity while boosting worksite efficiency and productivity.

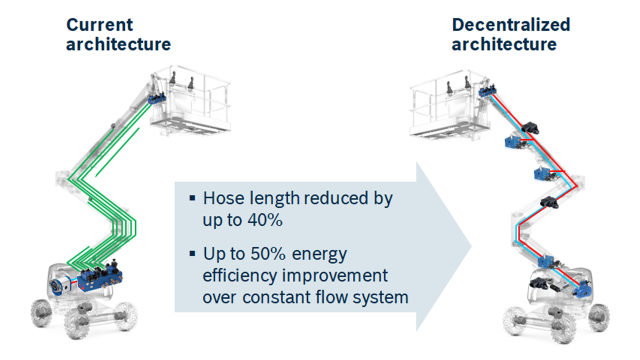

System Simplification

The DBC system utilizes common hydraulic lines and can reduce the required hose lengths by 40% compared to centralized solutions. On the left, are the current hoses required for the central manifold system, and on the right, the required hoses for the decentralized system. When the same size boom lift system of 45 ft (15.24m) is compared, the central manifold system requires 88.4m of hoses and the DBC system requires 46.4m of hoses.

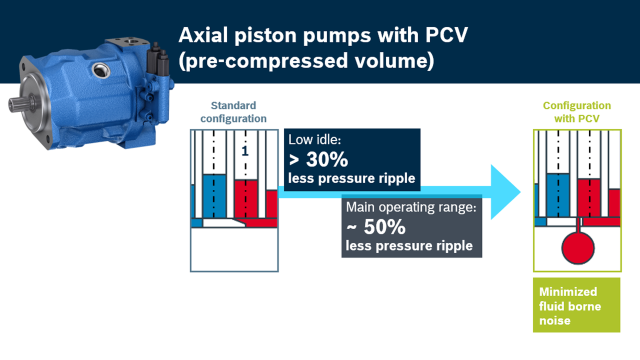

Improved Noise Reduction

Machines/applications with a high share of fluid borne noise as overall noise can benefit from pumps configured with the pre-compressed volume (PCV) option. The PCV can reduce fluid borne noise on average by as much as 10db(A).

With the SILENCE PLUS, Rexroth introduces a new generation of external gear pumps whose noise level has been reduced by an average of 15 dB(A) compared with a conventional external gear pump. The new pump is also characterized by a subjectively much more pleasant, deeper sound. The SILENCE PLUS is of special interest for use in applications with electric motor drives -- for example in fork lifts, lift platforms or industrial power units. Such drives then become significantly quieter in pressure ranges up to 280 bar.

DBC Functionalities

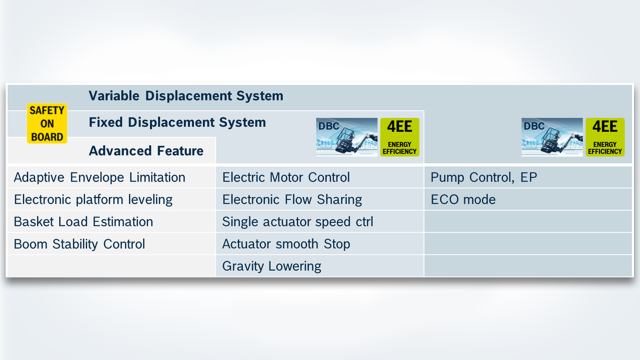

The core enabler of the decentralized architecture is the software handling the machine electronic flow sharing. This algorithm ensures smooth operation of simultaneous movements but also seamless transitions between single and multiple actuator control. A key system component is the MM7 inertial sensors installed in the boom structure, which allow for the very accurate estimation of the structure angular positions. Additional value is added with these components through functions like electronic cylinder smooth-stop as well as single actuator electronic speed control and regulation.

Perfecting the Mobile Elevating Work Platform

With the SILENCE PLUS, Rexroth introduces a new generation of external gear pumps whose noise level has been reduced by an average of 15 dB(A) compared with a conventional external gear pump. The new pump is also characterized by a subjectively much more pleasant, deeper sound. The SILENCE PLUS is of special interest for use in applications with electric motor drives -- for example in fork lifts, lift platforms or industrial power units. Such drives then become significantly quieter in pressure ranges up to 280 bar.

Need More Information about DBC?